HAPPY FESTIVE SEASON TO EVERYONE ! Welcome the New Year of opportunities. Our preceding posts address major quality gaps of integrity engineering. Is there a panacea solution? We believe: Yes! This article encompasses all we have presented earlier in this blog and bonds these topics together. This is our engineering philosophy for a new, better year coming.

Situation Analysis

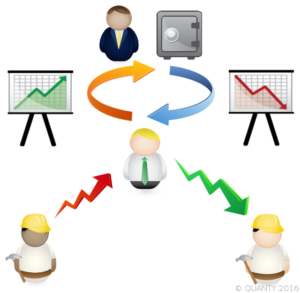

A Christmas tree is an amazing sight: So beautiful! The lights are blinking, running here and there. Everything is shiny. Looks like an action, but no, these are rather visual effects with no other use. Certainly, our organizations aren’t created for visual effects , but still, there can be internal spectators judging the business process entirely by its appearance. For example, someone responsible for safe and reliable operation of an equipment encountered integrity condition deviations. Say, inspections found small cracks in a pressure envelope. How to handle this situation, and what is the trigger for a shutdown/repair or for continued operation? A good appearance option is: simply doing same as in the past providing that the contractor is the cheapest for the scope work indeed. The job will run hopefully smooth and within the time-frame, right? Watch the magic: we just substituted the outcomes quality by the project management convenience. Many assume that traditionalism reinforces safety. This is often not the case, as we deal with the Reality of engineering problems (more in this post). Only the adequacy of engineering outcomes promotes plant operations safety, providing that these outcomes are followed up by a risk management process. Traditionalism has not much to do with risks, as in engineering we encounter new and specific issues on an everyday basis. This speech is not about neglecting experience, but about prioritizing risk controls adequacy over their simplicity or low cost. More specifically, what we actually observed is not even adhering to traditions and past knowledge, but rather lowering the services quality in the favor of lower costs. How will that facilitate a sustainable business future? Would you agree that a longer term thinking is safer? In turn, a money driven decision making narrows down the pool of contractors, hence, deflates the problem solving potential of the contractors pool. The cost pressure also simplifies the contractors themselves, as some advanced engineering activities become ‘too expensive’ in a short sighted perspective, hence are unused, forgotten, lost. And it will take a lot of effort to restore the knowledge over time when needed. Will robots be helping us then?

Constructive Solution

Let’s get back on the constructive track. There are many good voices: the Australian Oil&Gas industry aims taking on board more innovation for a better commercial efficiency. These top management aspirations are similar to replacing the former Christmas tree by a novel Christmas train, for example like this:  Trains do have capabilities to run towards a renewed, more efficient industry and economy, as opposed to old traditional Christmas trees. The rails are culture and effective communication. But how to facilitate the transition exactly? Happy to share this secret: Business development is possible following a technical development stage. Industry development is feasible following conceptual changes in decision making. These changes refer to costing risks (as discussed here) with a major emphasis given to the engineering problems Reality. Specifically, via respecting the Nature laws, as opposed to making subjective decisions in view of routine constraints. Luckily, our input is ready to apply. We developed a new Risk Based Inspection and Maintenance strategy (CoRBI®). It offers a genuine compliance and adequate decision support. All that rests on the engineering science for modeling your individual equipment condition, life expectancy and cost/benefit implications. This service offer brings the integrity and decision making confidence to the highest level by allocating rather a traditional amount of resources. We created a web interface to our advanced services and capabilities be accessible globally, as outlined in this post. Stay tuned, together we can make the new year positively different. We’ve got the train. We need your rails to ride together.

Trains do have capabilities to run towards a renewed, more efficient industry and economy, as opposed to old traditional Christmas trees. The rails are culture and effective communication. But how to facilitate the transition exactly? Happy to share this secret: Business development is possible following a technical development stage. Industry development is feasible following conceptual changes in decision making. These changes refer to costing risks (as discussed here) with a major emphasis given to the engineering problems Reality. Specifically, via respecting the Nature laws, as opposed to making subjective decisions in view of routine constraints. Luckily, our input is ready to apply. We developed a new Risk Based Inspection and Maintenance strategy (CoRBI®). It offers a genuine compliance and adequate decision support. All that rests on the engineering science for modeling your individual equipment condition, life expectancy and cost/benefit implications. This service offer brings the integrity and decision making confidence to the highest level by allocating rather a traditional amount of resources. We created a web interface to our advanced services and capabilities be accessible globally, as outlined in this post. Stay tuned, together we can make the new year positively different. We’ve got the train. We need your rails to ride together.

Happy New Year 2018 and Best wishes!

P.S. We can only change the world to the extent that we can change ourselves. We can only change ourselves to the degree that we become aware of our mistaken certainties. Most of our trouble arise from expectations, which have not become realities. Most of our disappointments come from our mistaken ideal of how we think the world should be, and what we think we “should” or “ought” to do, be or have. This is known as resisting reality… from: Dr Robert Anthony, “The ultimate secrets of total self-confidence”, 2003. To learn more about CoRBI® you can watch YouTube videos at our main page of simply flick us a message via the contact form.