1 Solution to 8 Weak Perspectives of Asset Integrity Digitalization

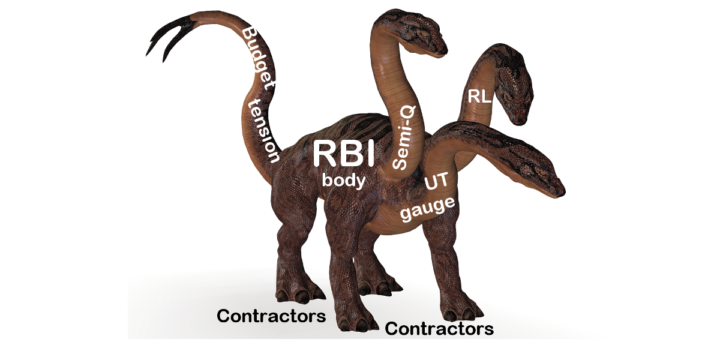

The ongoing push for digitizing petrochemical industries has some valid reasons for plant operators reluctance to it. While certain digitalization elements deserve a praise in a generic context, applicability constraints do apply in specific areas. One of such challenging applications is the Asset Integrity market, e.g. engineering problems and services relevant to operational degradation of equipment and its failure risk control. We firstly glance at the eight categories of novel offerings, as shown in the picture, in this very context. Then we will outline one adequate solution for a failure risk control effective upgrade towards better confidence, sustainability and safety. This is achievable right now and at a minimum change requirement. Disclaimer: This article is not a comprehensive text on the above digitalization pillars. It outlines a high level critical…